What is a diode array module?

There are different technologies used for creating laser light in showlaser industry. Common ones nowadays are

- DPSS (Diode Pumped Solid State Lasers), that use the resonator principle for creating laser light

- The diode technology, which uses high performance semiconductor technology (LEDs) together with some optics

- OPSL (Optically Pumped Semiconductor Laser), which more or less combines the resonator principle with semiconductor technology

Laser diodes are special amongst the other solutions, as they have special characteristics:

Whereas it is possible to create rather high powers of several Watts with one laser head of DPSS or OPSL, laser diodes are rather limited in power per single diode. To get higher powers, several diodes need to be combined.

Another limitation is the light color created with diodes: The colors of a laser depend on the active laser material, in the case of a diode laser this is the semiconductor. That's why only red (ca. 637nm) and blue (445nm) are common colors for diode lasers at the moment, as the semiconductors used for those colors are stable and can be produced at reasonable price quality ratio. Diode laser sources in green color have been developed by OSRAM at a wavelength of 515nm in 2013.

As mentioned above, the power per single diode laser source is limited. Those are the limits at the moment:

- red 637nm: max. ca. 170mW per single diode (single mode)

- blue 445nm: max. ca. 1500mW per single diode

- green 515nm: max ca. 150mW per single diode

To generate higher powers it is necessary to combine those low powered diodes to a module with higher powers.

Two principles are used for doing that:

Combination over polarization cube

A polarization cube is used for combining two diode modules of different polarization. Every diode can have be used in two different polarizations (let's call the A and B). With the polarization cube it is possible to combine one diode with polarization A with one diode polarization B.

It is not possible to combine one A with two B or similar. It is also not possible to combine an already combined beam with another one (AB with A) with the polarization cube principle.

The advantage of the polarization cube combination is, that two diodes are combined to be one point after the combination.

If more than two diodes need to be combined, the common solution is the ...

Combination by Knife Edge Combination

The principle of Knife Edge Combination combines several laser diodes by laying the very beams very close to each other with the use of small mirrors. This of course leads to physically not having one beam coming out of the module, but several small beams very close to each other. Human eye receives that as one beam.

Usually the Knife Edge Combination is done in two layers, one layer with polarization A and the other one with polarization B, so after having combined the very layer by Knife Edge Combination, the two layers can be combined over a polarization cube. This has the advantage that the number of single dots generated through the knife edge combination can be reduced by half - this is a huge advantage für visibility and beam quality.

Quality differences of diode array modules

Depending on the materials used and the precision in manufacturing, there are huge differences between the diode array modules available in the market.

RTI (Ray Technologies) ins an expert ihn high end high precision manufacturing of laser diode array modules. The very precise alignment of the single diodes and the resulting very small laser beam with great beam specifications result from

- extremely precise aluminim milling

- the right choice of materials (temperature stability is extremely important)

- the use of advanced electronics components developed and Made in Germany

- the use of professional TEC modules that are adapted to every single module to provide optimal performance

- fine-adjustable Knife Edge Combination mirrors

- the use of optical components with very low loss

- an advanced thermal management

Why is it so important to have the laser beam as precise as possible?

It's obvious: The thinner and more precise the beam, the longer it reaches, as it doesn't lose so much power on the way.

But there are several other cases why it is so important to get quality diode array modules: If a larger beam (consitsion of several single-diode beams) needs to be handled together with a scanning system, it is very important to be able to use small scanner mirrors, because inertia increases dramatically with the size of the mirrors. And obviously this leads to dramatically reduced scan speed and scanning accuracy.

RTI diode modules have an extremely precise beam and can even be used with the very small CT-6210 scanner mirrors - a huge advantage for scanning quality.

Example of a non-precise Knife Edge Combination (bad):

It is even possible to count the single diodes on the front glass of the diode array module. There is a lot of space between the beams. Huge scanner mirrors are necessary to handle the fat beam, which results in reduced scan speed, especially if it comes to larger scan angles.

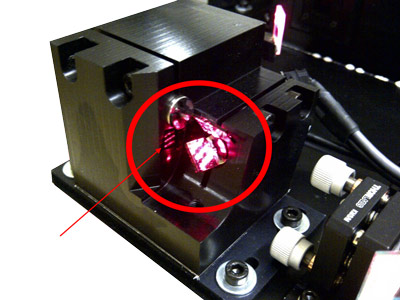

Very good solution: RTI Diode Array Modules

One single point, single diodes cannot be counted. All colors match in one point without any blur.

Please see the small mirrors that can be used! Higher scan speeds and large scan angles are possible due to the reduced inertia of the mirrors:

See our high precision products with RTI diode Array Modules:

Distributed brands: